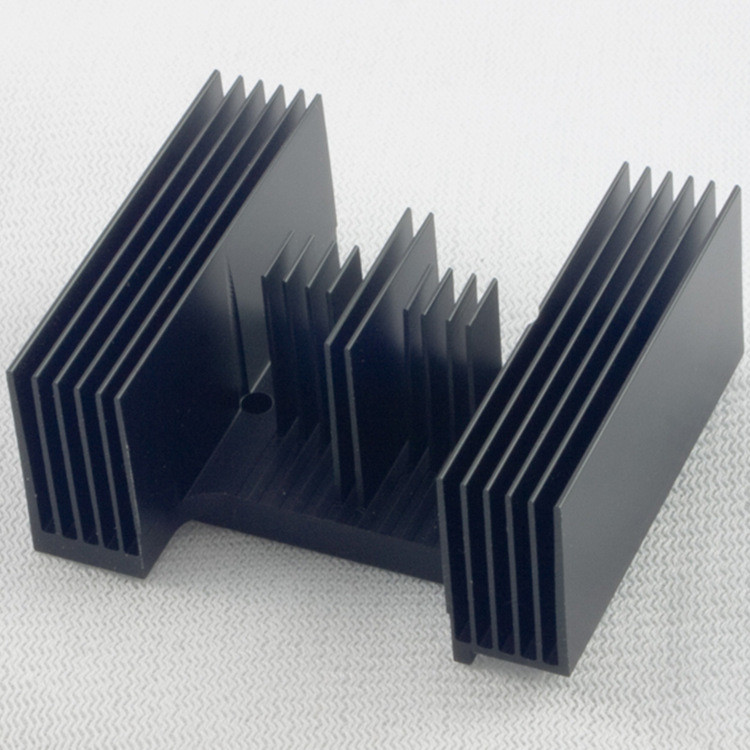

Pros and Cons of Machined Aluminum Heat Sinks

- Share

- Issue Time

- Jun 16,2021

Summary

Many heat sink designs require machining in order to make sure that they deal with the heat management challenge that they were designed to address.

Many heat sink designs require machining in order to make sure that they deal with the heat management challenge that they were designed to address. Because precision CNC machining can create more complex shapes (geometries) than can be produced using other heat sink design methods, this provides some big design advantages:

More efficient heat transfer

Machined heat sink design that needs to fit a specific profile within an electronic device

Designs can be changed based on testing results in a lab or in the field

But machined aluminum heat sinks do have some drawbacks, especially when they are cut from solid blocks of premium grade aluminum billet:

Generates more waste – Cutting the design out of a solid block chips away the aluminum that is not needed and might be wasted

Take more time to produce – Machined aluminum heat sinks take longer to produce than using other methods such as aluminum extrusion and pressed folded fin heat sinks

More expensive – Because more steps are involved in the production process, and machined aluminum heat sinks take more time to produce, they are more expensive than heat sinks produced using other methods.